Description

Subsea ROV (remotely operated vehicle) is an underwater vehicle that is controlled remotely by an operator on the surface. It is commonly used in offshore industries such as oil and gas exploration, marine research, and underwater construction.

Subsea ROVs are typically tethered to a surface support vessel, which provides power and communication to the ROV. The ROV is equipped with cameras, lights, and sensors that allow the operator to see and manipulate objects in the underwater environment.

ROVs come in a variety of sizes and designs, from small portable systems that can be operated by a single person, to large work-class ROVs that can lift heavy equipment and perform complex tasks. They can operate at depths of up to 6,000 meters or more, and are used in a wide range of applications, from inspecting pipelines and underwater structures to performing scientific research and exploring the deep sea.

Introduction to ROV Components, Intervention, Interface Requirement & Tooling Mechanism for Subsea Project Engineers & Entry Level Pilot Technicians (ROVIRTMSPEELPT) Level 1 covers overview of the state of the art for subsea remote intervention and vehicles, ROV technologies, and ROV capabilities and requirements for subsea operations, ROV Intervention Operations for Site Survey, Drilling Assistance, Installation Assistance, Operation Assistance, Inspection, Maintenance and Repair, ROV Intervention System, ROV Machine etc. ROV interface requirements based on API 17H, Remote-Operated Tool (ROT) and more.

Course Outlines

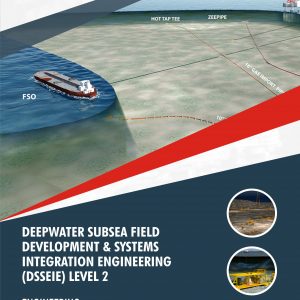

Subsea Production Systems

Subsea Field Architecture

Subsea Distribution Systems

Offshore & Subsea Surveys

Subsea Structures Installation and Vessels

Subsea Cost Estimation

Subsea Control Systems

Subsea Power Supply

Subsea Project Execution and Interfaces

Introduction to Remote Operation Vehicle & Intervention

Case Studies of ROVs & Specifications i.e. Mohawk, Super Phanton S2, Phantom 300 and Saab Seaeye eWROV

Factors Affecting ROV Operations

ROV Personnel Requirements & Responsibility

Training and Qualifications

Minimum Equipment needed for an ROV Mission

Integrated Navigation System (INS)

ROV Video Recording, Scientist Supplied Equipment & Shipment

ROV Project Mission Record Keeping and Documentation

Video Recording Procedures & Maintenance

Site Survey

Drilling Assistance

Installation Assistance

Operation Assistance

Inspection

Maintenance and Repair

ROV Intervention System

ROVs Categories

ROV Systems Topside Facilities

ROV Launch and Recovery Systems (LARS)

Umbilical and TMS

Characteristics of ROV Systems

Requirements for the typical interfaces based primarily on API 17H

Stabilization Tool

Handles

Torque Tool

Hydraulic Connection Tool

Linear Override Tool

Electrical and Hydraulic Jumper Handling Tool

ROT Configuration

Pull-In and Connection Tool

Component Change-Out Tool

Introduction to Piloting Underwater ROV

A Case Study of Panther XT Plus ROV

ROV Pilots Operating Environment

ROV Optimization

ROV Crew

ROV Buoyancy and Stability

Introduction to Operational Procedures

Communications

Deployment and Recovery

Pre and Post Dive Check List

Post Dive Procedures

Emergency Operations

Tether in Vessel’s Propeller (s)

Tether Severed Completely

Hours of Operation

Operation Modes

Live Boat Operations

Night Operations

ROV Maintenance

Appendix 1: Downloadable Sample of ROV Dive Log for Supervisors

Appendix 2: Downloadable Sample of Minimum ROV Components Checklist for Supervisors

Appendix 3: Downloadable Sample of ROV Pre Dive Checklist for Supervisors

Appendix 4: Downloadable Sample of ROV Post-Dive Checklist for Supervisors

Appendix 5: Downloadable Sample of ROV Trouble Report Form for Supervisors

Appendix 6: Downloadable Sample ROV Piece Weight List Form for Supervisors

Appendix 7: Downloadable Sample ROV Mission Coordination Daily Log for Supervisors

Appendix 8: Downloadable Sample of ROV DIVE Summary for Supervisors

Appendix 9: ROV Tether Management for Supervisors

Technical Support References

Ref 1: Overview of ROV systems and their applications in subsea operations

Ref 2: Types and classifications of ROVs

Ref 3: ROV components and their functions

Ref 4: Introduction to ROV control systems and communication interfaces

Ref 5: ROV intervention methods for subsea operations

Ref 6: Manipulator arms and tooling systems used in ROV interventions

Ref 7: Understanding ROV sensors and imaging systems for visual inspections and data collection

Ref 8: ROV navigation and positioning techniques

Ref 9: Subsea infrastructure and equipment interfaces for ROV operations

Ref 10: Interface standards and guidelines for ROV integration

Ref 11: Umbilical management and tethering systems

Ref 12: Power and data transmission requirements for ROV operations

Ref 13: Overview of ROV tooling mechanisms used for subsea tasks

Ref 14: ROV-mounted cutting, gripping, and sampling tools

Ref 15: Tooling interfaces and compatibility considerations

Ref 16: Safety protocols and procedures for ROV operations

Ref 17: Risk assessment and hazard identification in subsea environments

Ref 18: Maintenance and inspection practices for ROV systems

Ref 19: Case studies and lessons learned from real-world subsea projects

Ref 20: Overview of relevant industry standards and regulations governing ROV operations

Ref 21: Compliance requirements and documentation for subsea projects

Ref 22: ROV operations environmental considerations and mitigation measures

Ref 23: Exploration of emerging technologies in ROV systems

Ref 24: Trends in autonomous and unmanned subsea operations

Ref 25: Discussion on the future of ROV systems and their impact on subsea projects

Ref 26: Piloting Underwater ROV

Ref 27: ROV Operational Procedures

Ref 28: ROV Operations JSA

Ref 29: ROV Mobilization Procedures with JSA

Ref 30: ROV Demobilization Procedures with JSA

Ref 31: A case study of ROV Mobilization & Demobilization

Assessment

Participant underpinning knowledge of ROV Intervention, Interface Requirement & Tooling Mechanism will be accessed with short answer multiple-choice questionnaire at the conclusion of the course.

Outcome

Participants will gain an in debt understanding of ROV Intervention, Interface Requirement & Tooling Mechanism .They will also be able to function with minimum supervision as Offshore Engineers, Technicians & Subsea Engineers, Subsea ROV Technician, Subsea Project Engineer for IOCs, Offshore Drilling & Installation Contractors.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe.

Participant may be presented for Offshore Petroleum Training Organization (OPITO) Certification.

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.